“Order picking is one of the fundamental steps in the order dispatching process. Each picking operation is triggered by the reception of a customer order form. “Picking” designates the supply chain operation during which products are removed (“picked”) from a storage area before consolidation and shipment to the customer.

Picking is a time-consuming and tedious task, and errors can occur.

Picking represents more than half of a distribution centre’s operating costs. Customer satisfaction depends largely on the successful execution of this operation, and companies pay particular attention to it.

How can you optimize your order picking methods to make them fast, reliable and accurate? Read on for more info, and discover the 3 most common errors - so you can avoid them.

How is order picking organized?

© A warehouse worker / Halfpoint

In the distribution centre, operators prepare a package in 4 order picking steps:

- Picking: the articles needed to make up one or more orders are picked from storage.

- Sorting: picked articles are dispatched to their respective orders.

- Packing: the articles are packed before being grouped.

- Pre-shipping inspection: the order picker checks the weight of the completed order and scans the barcode on its label to ensure track and trace of the package.

These steps ensure that the 3 principal goals of order picking are achieved:

- optimized stock management,

- customer satisfaction, and

- the safety of stock, customer orders and operators (strict enforcement of hygiene and safety rules etc.).

3 errors to avoid when picking orders

1- Not taking into account the human factor in order picking

Stress, carelessness, mishandling, fatigue... To err is human, and error is impossible to eliminate.

This factor should not be overlooked by warehouse managers, as it can impact process quality and customer confidence. So what’s the best way to manage this aspect?

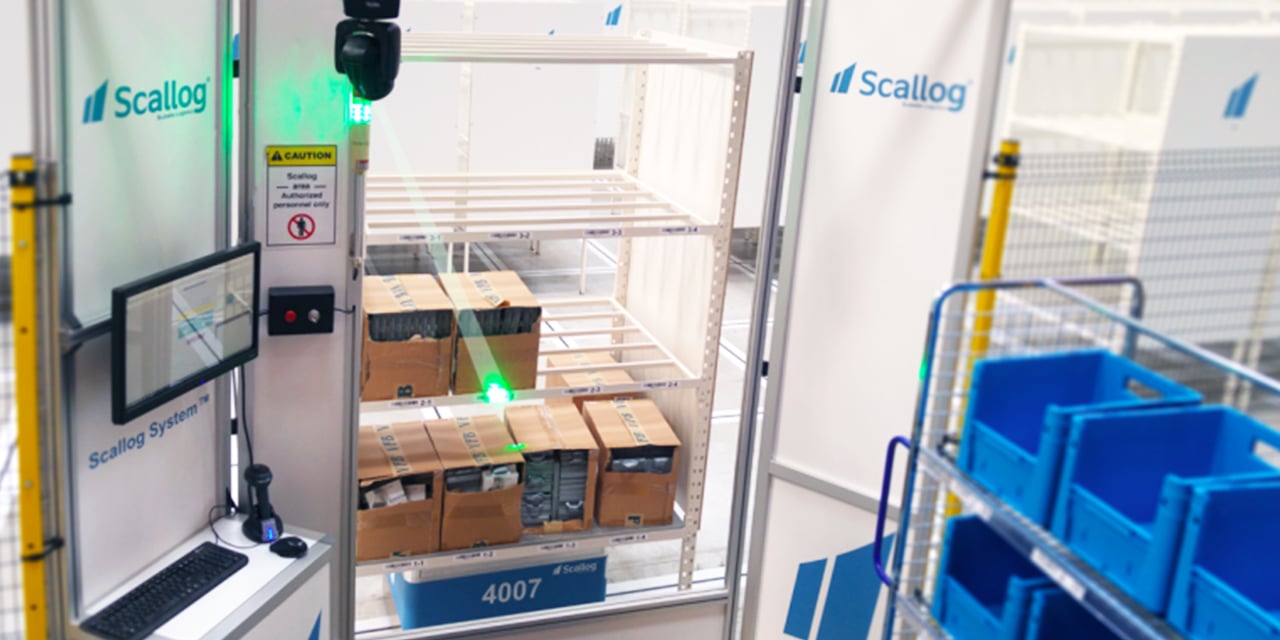

Scallog offers a robotics solution with an integrated Spot-to Light function.

A light beam guides the operator to the products to be picked, then points to the destination tray in the buffer rack. This reduces the risk of picking the wrong article:

- no more picking an article whose stock number is close to the required article

- no more articles left out

- no more mixing of multiple commands

- no more articles of the wrong size

- etc.

The Scallog system makes picking reliable.

© Spot-to Light / Scallog

2- Stock errors

Unlike physical stores that are subject to stock limits, e-commerce sites are able to offer an unlimited number of products.

In theory, everything posted on an e-commerce website should be available. However, in practice, there are cases where items may be out of stock as a result of erroneous stock estimates. The customer is then charged for a product that she will not receive, or not for a long time at least.

Scallog helps prevent this risk of customer dissatisfaction.

The Scallog system integrates with the capabilities of the WMS (Warehouse Management System) or ERP (Enterprise Resource Planning) solution already implemented in the distribution centre by WCS (Warehouse Control System) software.

Therefore, during picking, operators can view the stock level of each product in real time, and are notified if a product has been placed in the wrong slot.

© Spot to Light / Scallog

3- Miles of aisles

The floor area of a warehouse can be vast, and this makes order picking tedious.

In addition to the physical distances covered, the organization of stock in a warehouse can also be problematic when it comes to picking.

For order pickers, the task gets even more difficult when they have to deal with:

- large stock with many product references

- misplaced stock

- badly structured stock

- etc.

If items are not stored optimally, finding the most efficient route and consolidating the right product references in the right quantities can become a lengthy and exasperating exercise. And mistakes are likely to happen in such situations.

The secret of successful picking lies not only in the well-being of your operators but also in the right storage structure.

Optimizing your storage space is essential to ensure your operators benefit from the best working conditions and the shortest distances to travel. How can this be achieved?

By securing a 30% reduction in storage space, the Scallogsolution significantly reduces the distances covered by order pickers..

- Hugues Sterlin, Operations Manager at Scallog

Not only that, but the goods to man system means operators don't have to move around at all - a Boby robot brings the shelf units to the operator. With the Scallog solution, operators benefit from improved quality of life at work thanks to:

- a reduction in distances travelled (from 15 to 12 km),

- increased safety,

- an ergonomic workstation

All these benefits add up to a reduction in order picking times. In fact, operator productivity increases threefold.

Errors during picking can occur for many reasons. Identifying the causes of error is the first step toward eliminating them. However, finding the best automation solution for your order picking process can be a complex undertaking.

Our advice is to call on the assistance of professionals, who will guide you towards the most ambitious logistics solutions possible.

Scallog is well placed to advise you on this as it offers a robotics solution that combines reliability, robustness and agility, all with reasonable installation costs.

Contact us to assess your needs and move to a more human logistics solution.

Laisser nous votre commentaire